Air Spring Breakdowns or Air bags as they are commonly referred too are a common, expensive, and time-consuming roadside breakdown for commercial trucks and trailers. Because there are hundreds of different sizes and configurations of Air Springs (air bags) it is unlikely that a mobile road service provider like Allewell Truck and Trailer will have to correct air spring (air bag) in stock on their mobile service truck. Because of this, service calls for Air Spring (air bag) failures require a lot more time due to the need to source out the correct part and the travel needed to acquire the part from the suppler. The customer always pays for this time. Often due to the number of variations in Air Springs (air bags) or the operating hours of parts suppliers, replacement air springs (air bags) are not always readily available. This results in extended down time on the trucking company which could result in increased costs. Majority of Air Spring (air bag) failures are preventable. Air Springs (air bags) are one of the most neglected parts on any semi-truck and semi-trailer. This is due to a lack of knowledge and more so a general bad attitude from managers and mechanics that the condition of rubber on an Air Spring (air bag) is not that important. In my opinion 95% of all Air Spring (air bag) failures is a direct result of incompetent preventive fleet maintenance. The only time that an Air Spring (air bag) failure is not that direct cause of incompetent preventive maintenance is when road debris strikes the air spring and damages it. Yes, road debris failure of air springs (air bags) does occur, but almost all failures that happen are because of the breakdown in the rubber and cord reinforcement sections of the air springs (air bags). They fail in two ways, the reinforcement sections breakdown to the point that they start to leak air, or the sections breakdown and result in a catastrophic blow out of the air spring (air bag).

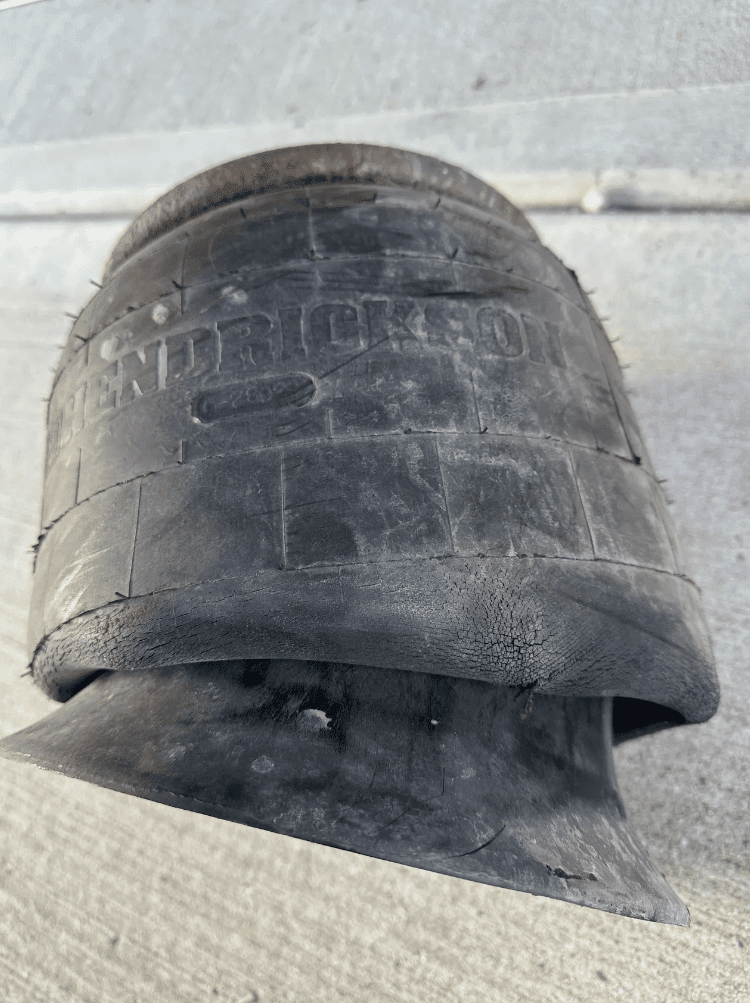

I have firsthand witnessed this lack of knowledge and poor attitude regarding replacing air springs (air bags) during regular preventative fleet maintenance inspections from my own Service Mangers/Advisors and Diesel Truck Mechanics as well as directly dealing with many Fleet managers on the issue. It is the opinion of too many, that cracks in the rubber of an air spring (air bag) are not a reason to replace an air spring. In Canada, National Safety Standard 11 (old standard) and National Safety Standard 11B (new standard) both say the exact same thing regarding air springs (air bags) “No air spring or airbag shall be improperly seated, missing, patched or have a reinforcing ply exposed due to damage or deterioration or have any air leak present.”. Exposed reinforcing ply damage or deterioration means only one thing. When an air spring (air bag) is inspected, if you can see the cords then the air spring (air bag) fails inspection. The air spring (air bag) MUST be replaced as it is unsafe by definition in National Safety Standard 11 and 11B.

The cost of replacing a single Air Spring (air bag) during a side of the road breakdown can is some cases equal the cost of replacing four air springs (air bags) in a shop during a preventative maintenance inspection. If you are an owner or a fleet manager, you should be questioning every single air spring (air bag) failure that occurs as it is most likely due to improper preventive maintenance.

Allewell Truck and Trailer provides many roadside breakdown services, including replacement of air springs (air Bags). If you need roadside service in the London, Ontario highway 401 area call 519-868-8141 for fast quality service.