In the realm of commercial vehicles, hydraulic systems play a crucial role, powering everything from lift gates and steering systems to brake mechanisms and suspension. These systems, known for their efficiency and reliability, require meticulous maintenance to prevent downtime, ensure safety, and extend the life of the vehicle. Allewell Truck and Trailer is committed to providing expert insights into the essentials of hydraulic system maintenance for commercial vehicles.

Understanding Hydraulic Systems

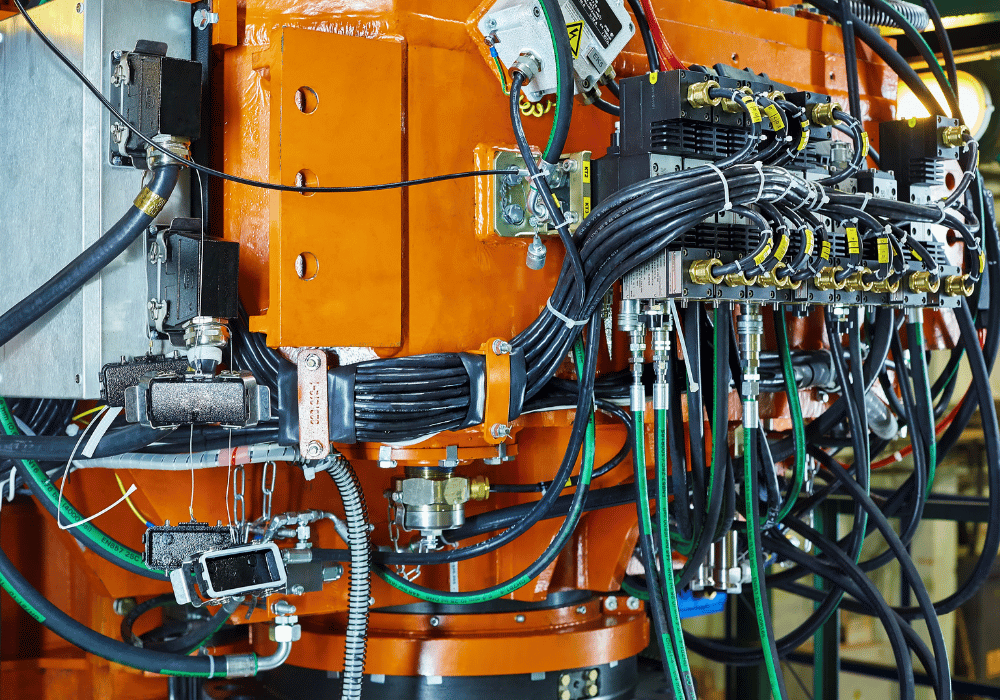

Hydraulic systems operate on the principle of fluid mechanics to transmit power. They consist of several components, including pumps, hoses, cylinders, and fluid reservoirs, each integral to the system’s overall performance. The efficiency of a hydraulic system lies in its ability to apply force smoothly and precisely, making it indispensable in heavy-duty commercial vehicles.

Regular Fluid Checks and Changes

The lifeblood of any hydraulic system is its fluid. Regular checks are crucial to ensure the fluid is at the correct level and free of contaminants. Contaminated or degraded fluid can lead to inefficiencies, component wear, and system failure. Fluid changes should be scheduled based on the manufacturer’s recommendations or signs of fluid degradation, such as discoloration or the presence of particles.

Inspecting and Replacing Hydraulic Hoses

Hydraulic hoses endure significant stress, transferring high-pressure fluid between system components. These hoses can become the system’s weak link if not properly maintained. Regular inspections can identify wear, leaks, or damage that could lead to catastrophic system failure. Replacing hoses before they fail is a cost-effective strategy to prevent downtime and expensive repairs.

Monitoring System Pressure

Proper system pressure is essential for hydraulic systems to function correctly. Too much pressure can cause hose bursts or damage components, while too little pressure can lead to poor system performance. Regularly checking the system’s pressure and adjusting it according to specifications ensures the system operates within safe and efficient parameters.

Keeping Hydraulic Components Clean

Cleanliness is next to godliness in hydraulic system maintenance. Dirt, debris, and other contaminants can enter the system during maintenance or through breaches in the system’s seals. Keeping components clean and sealed against contaminants prevents internal wear and extends the lifespan of the system. This includes cleaning the area around access points before opening the system for maintenance or fluid changes.

Hydraulic system maintenance is a critical aspect of commercial vehicle upkeep that should not be overlooked. Regular fluid checks, hose inspections, pressure monitoring, and cleanliness are essential practices that ensure the system’s efficiency, reliability, and longevity. At Allewell Truck and Trailer, we specialize in maintaining and repairing hydraulic systems in commercial vehicles. Our team of experts understands the nuances of these systems and is dedicated to providing the best care to keep your fleet running smoothly.

For comprehensive hydraulic system maintenance and repair services, turn to the experts at Allewell Truck and Trailer. Our commitment to excellence ensures your commercial vehicles remain operational, efficient, and safe on the road.